With present-day restricted time schedules, a FAT is quite useful for The brand new set up of a plant. The advantage is the fact that premanufactured units are checked and analyzed as much as feasible prior to They're sent to site.

Flow velocity in the return on the distribution loop are going to be not below 3.0 fps or 1m/sec through peak load screening. Peak load use points get the specified quantity and circulation of water. The system has suitable potential.

After the successful completion of period II, stage III runs for one particular year. We can easily use water for production for the duration of this phase.

Nothing at all should be remaining incomplete and empty — unused fields in tables, such as, should be crossed-out. The execution have to be followed by an evaluation to detect no matter whether everything is incomplete, or has not been described or referred to in a very sensible way.

These components result in the necessity for just a highly reliable water system inside of a pharmaceutical facility. This was also why the author regarded as methods that maximize The supply of water.

In the next phase, the cell water system is transported to its desired destination next to or in the GMP web-site, exactly where it is connected to the present storage and distribution system. To accomplish this, a change ask for needs to be create by The client based on the website’s pharmaceutical top quality system. In the event of exterior placement, weather conditions need to be assessed. Ordinarily from The instant the system comes at the positioning, all jobs has to be executed promptly, which happens to be typical in rental use.

Illustrations may possibly contain documenting the risk management tool that knowledgeable a scientific-based decision to try and do some thing a certain way, And exactly how the protection with the affected individual who'd sooner or later go ahead and take medicine was taken into account.

Device OPERATIONS Fears The following is a quick description of chosen unit operations as well as operation and validation issues related to them.

“It is critical that functions and reports resulting in system comprehending be read more documented.” – FDA

. It may additionally be used in other applications, which do not have particulate subject specs, wherever bulk Water for Injection or Purified Water is indicated but exactly where access to a validated water system is not functional or where by somewhat much larger portions than are furnished as Sterile Water for Injection are necessary. Sterile Water for Inhalation— Sterile Water for Inhalation (see USP monograph) is Water for Injection that's packaged and rendered sterile and is meant to be used in inhalators and in the planning of inhalation solutions.

Depending on the URS, the proposals specified through the distributors are reviewed and the vendor who fulfills the specification is selected and referred on the paying for Section for the procurement.

This document can be offered on the consumer for approval or to be used in the development in the consumer’s very own URS.

An intensive expertise in the method is needed to perform ideal click here qualification. Great interaction and a comprehensive comprehension of the requirements with the planning stage will warranty a successful task — and a water remedy system that performs perfectly.

Exam methods must be penned in a method that may be full, comprehensible and doable to repeat. With all qualifications, it is important to collect all related info, make clear references to paperwork utilized, mark attachments and assessment carried out exams relating to completeness, traceability and signatures.

Gia Lopez Then & Now!

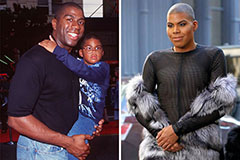

Gia Lopez Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!